Research

1. Research fields (discipline development)

The research in this division covers a broad field on chemistry and chemical engineering related to nuclear energy. Efforts span from assessing the fundamental chemistry of radioactive elements to developing applicable processes in the nuclear fuel cycle.

(1) Nuclear Energy Chemistry and Materials: chemistry and materials studies related to nuclear waste treatment and utilization.

(2) Nuclear Fuel Cycle: High Level Liquid Waste partitioning, pyro-reprocessing, actinide/lanthanide separation, apparatus for nuclear separation (centrifugal contactors, mixer-settler, pulsed column), reagents for nuclear separation (crown ethers, calix crown ethers), etc.

(3) Nuclear Hydrogen Production: I-S thermal cycle hydrogen production, hydrogen production through solid oxide electrolysis at elevated temperatures.

2. Research Projects

The division is well funded through a variety of projects. Selected projects under investigation include:

(1)High Level Liquid Waste partitioning

(2)Valence states and speciation of Np, Pu and Tc in nuclear fuel reprocessing

(3)Design and development of large-scale pulsed column

(4)Design and development of large-scale mixer-settler

(5)National Science Fund for Distinguished Young Scholars: actinide chemistry

3. Lab and facilities

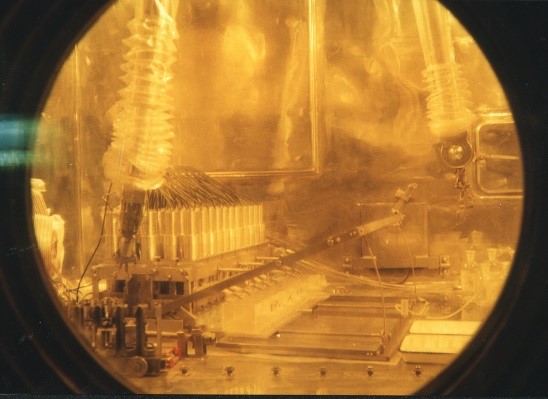

Radiochemistry Lab:

Approximately 3000 sq meters of radiochemistry lab space is available. The lab is licensed for alpha, beta and gamma radioisotopes for work with gram amounts of transuranic elements such as Np and Pu. The lab contains two hot cells, a suite of radiological hoods and a full array of radioactivity counting equipment, including liquid scintillation, alpha spectrometer, and gamma spectrometer.

Radiochemistry Lab

Chemistry Lab

The traditional chemistry lab contains extensive instrumentation for visible-ultraviolet spectrophotometry, microscopy (SEM, AFM), fluorescence spectroscopy, Raman spectroscopy, gas chromatography, high-performance liquid chromatography, ion chromatography, inductively-coupled-plasma-atomic emission spectroscopy, infrared spectrophotometry, X-ray diffraction, thermogravimetric analysis, etc.

Hot Cell

Centrifugal Contactors

4. Achievements

Awards

2017 Award for Progress in Science and Technology (2nd tier)

2003 National Award for Technological Invention (2nd tier)

1998 National Award for Technological Invention (2nd tier)

1993 National Award for Natural Science (3rd tier)

Publications

The division publishes about 50 papers annually. In recent years, research articles from the division have appeared in top-journals including Nature, Nat. Commun., J. Am. Chem. Soc., Angew. Chem. Int. Ed., etc.

Research Highlights

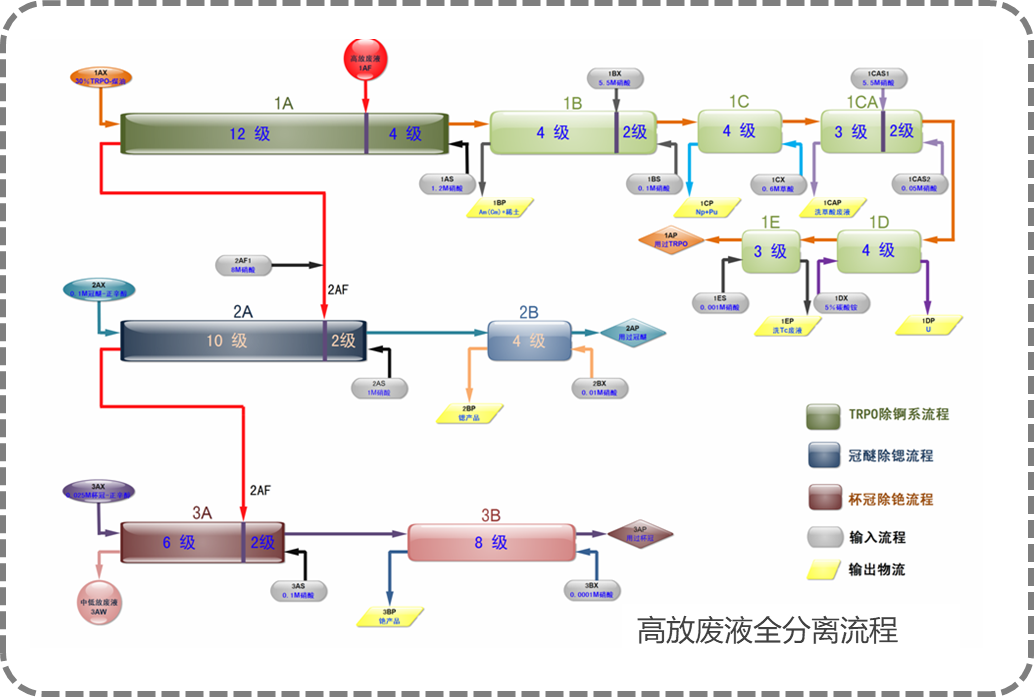

(1) High Level Liquid Waste Partitioning

The safe treatment of High Level Liquid Waste (HLLW) is of great importance to ensure the sustainable development of nuclear energy, yet it is a very challenging task. The “Partitioning & Transmutation” strategy has been regarded as an effective way to minimize the long-term radioactive hazard of HLLW.

From late 1970s, a team led by Prof. Yongjun Zhu at Tsinghua University started research work on HLLW partitioning. With continuous efforts over the past 40+ years, a total-partitioning process has been successfully developed. The process mainly contains three solvent extraction cycles: 1) removal of actinides, especially the minor actinides, by trialkyl phosphine oxides (TRPO); 2) removal of Sr-90 by crown ether (DCH18C6, DtBuCH18C6); removal of Cs-137 by calix crown ether. With this process, the HLLW can be transformed into medium or low level liquid waste, which can be more conveniently disposed. Meanwhile, isotopes such as Np-237, Sr-90 and Cs-137 of high purity can be obtained as products for re-utilization.

Flowsheet of High Level Liquid Waste Partitioning at Tsinghua University

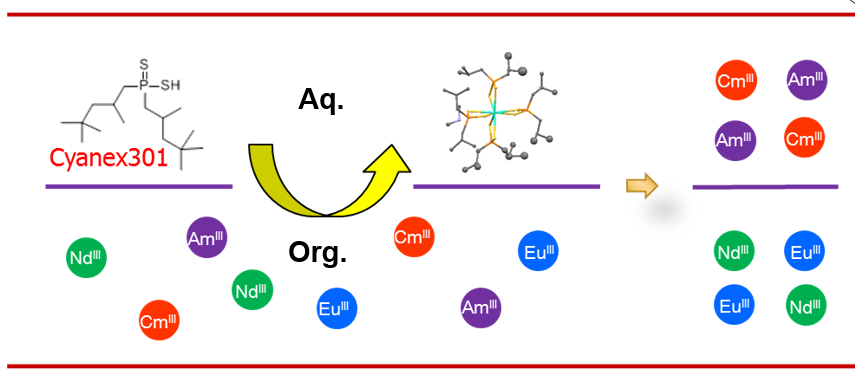

(2) Trivalent actinides/lanthanides separation

Separation of trivalent actinides from lanthanides is a key step in the “Partitioning & Transmutation” strategy. However, the chemical similarity between trivalent actinides and lanthanides makes their separation a seminal challenge. In 1990s, Prof. Yongjun Zhu and Prof. Jing Chen first noticed that the purified product (bis(2,4,4-trimethylpentyl) dithiophosphinic acid) of commercial Cyanex 301 reagents shows high selectivity to trivalent actinides (Am, Cm) over lanthanides. The finding has been regarded as one of the most significant progress in the area of trivalent actinides/lanthanides separation. Extensive efforts have been made then towards the understanding of the underlying chemical mechanism and the development of a separation process. The process has been successfully demonstrated on centrifugal contactors using genuine Am/Ln waste. In recent years, great progress on trivalent actinides/actinides separation has also been made by oxidizing Am(III) to Am(V) or Am(VI).

Trivalent actinides/lanthanides separation based on dithiophosphinic acid

(3) Centrifugal Contactors

Annular centrifugal contactor (ACC) is an efficient apparatus for liquid-liquid solvent extraction. Compared with mixer-settlers and pulsed columns, ACCs have a smaller liquid hold-up volume and shorter liquid residence time, thus allowing fast separation and decreasing the radioactive degradation of the solvent. Their more compact design also reduces physical space requirements and improves criticality safety. ACCs are expected to play a more important role in advanced nuclear processing schemes. A series of ACCs of different sizes have been developed at Tsinghua University and have been successfully applied in nuclear industry.

Centrifugal contactors of different sizes developed at Tsinghua University

5. Contact Us

| Chao XU | xuchao@tsinghua.eud.cn |

| Xuegang LIU | liu-xg@tsinghua.edu.cn |

(Last updated:2024-05) |

|