Research

1、Research fields

The New Energy and Materials Chemistry Laboratory currently focuses on key materials and technologies in the fields of hydrogen fuel cells and secondary batteries, conducting cutting-edge innovative research, as well as foundational research and engineering development on core components, system integration, and control technologies. In response to the significant demands of new energy vehicles and energy storage, the research team prioritizes the development of new power (energy) technologies with high safety, long lifespan, and environmental friendliness. The team currently mainly carries out research on physical adsorption hydrogen storage technology, ultra-high specific energy lithium-ion battery technology, power battery safety technology, low-cost long-life fuel cell technology, key materials and components for hydrogen-electric conversion, stack (electrolyzer) design and optimization, and related forward-looking technologies; direct alcohol fuel cells; medium-low temperature solid oxide fuel cells, and new energy storage technologies. In recent periods, they also started innovative research on advanced photolithography resists and porous material technologies based on metal-organic frameworks (MOFs) and covalent organic frameworks (COFs); as well as microbial electrochemical technologies.

2、Research projects

The research laboratory has undertaken more than 10 projects funded by the Ministry of Science and Technology's "973" program, "863" program, key R&D planning projects, and intergovernmental international cooperation projects. It has also been involved in over 20 projects funded by the National Natural Science Foundation of China, including youth foundation projects, general foundation projects, and key foundation projects. In addition, the laboratory has collaborated on more than 30 joint research projects with renowned international corporations such as Apple, Boeing, Mercedes-Benz, BMW, South Korea's LG, and Foxconn. It has completed over 40 horizontal entrusted R&D projects with enterprises.

3、Laboratory and facilities

The research laboratory has an experimental space of over 2000 square meters, which includes chemical synthesis laboratories, analytical testing laboratories, clean room, drying room, and hydrogen gas room. It is equipped with specialized devices and equipment such as microwave synthesizers for nanomaterials, a continuous flow reactor with independent intellectual property rights, dispersion equipment, cleaning and filtering machines, positive pressure filters, freeze-dryers, high-speed Cryocyclone, rotary tube furnaces, ball mills, and other specialized devices and equipment; for analysis and characterization, there are Thermo Fisher Antari II FT-NIR Fourier transform infrared spectrometers, GE Ultrospec 5300 pro UV-visible spectrophotometers, Shimadzu UVmini-1240 UV-visible spectrophotometers, Shimadzu liquid chromatography-mass spectrometry LCMS-2010EV, Agilent 7890A gas chromatographs, comprehensive thermal analyzers, Zeiss AX10 microscopes, Zahner Im6e electrochemical workstations, Solartron electrochemical workstations, and other equipment; for membrane electrode preparation, there are SONOTEK ultrasonic atomizing spray systems, electrode hot pressing machines, edge sealing machines, dispensing machines, and other specialized equipment; battery testers; large instruments and equipment such as in-situ XRD, BET, TGA/DSC, ARC, SEM, and other large instruments and equipment. In addition, the material calculation platform in the laboratory includes a 980-core computing cluster and related computational software (such as Materials Studio 7.0, Gaussian 16, VASP 6, etc.).

|

|

| Fuel Battery Lab | Lithium Ion Battery lab |

|

|

| High safety Lithium Ion Battery | Fuel cell design and integration |

4、Academic achievements

Awards

2023 Beijing Science and Technology Award for Technological Invention, First Prize

2023 Beijing Science and Technology Award for Science and Technology Progress, Second Prize

2023 China Nonferrous Metals Industry Science and Technology Award, Second Prize

2018 Hubei Science and Technology Award for Invention, Third Prize

2018 The 10th International Invention Exhibition Gold Medal for Invention

2014 Beijing Invention Patent Award, First Prize

2011 The 20th National Invention Exhibition Gold Medal for Invention

2010 The 19th National Invention Exhibition Gold Medal for Invention

Publications

Average 30 high level papers published each year

Research achievements

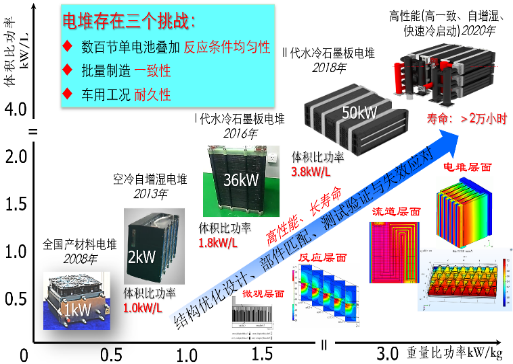

(1)High-performance Vehicle Fuel Cell Stacks and Industrialization

The development of fuel cell stacks is a systems engineering that encompasses multiple fields and disciplines, including design, materials, technology, and testing. Stacks are typically composed of hundreds of fuel cell cells connected in series, presenting challenges in terms of uniformity of single cell reaction conditions, consistency of component quality, and durability in application. Since 2006, when the Ministry of Science and Technology's "863" project for localizing fuel cell stacks was undertaken, the first 1KW stack in China was developed. Through multiple rounds of stack structural optimization design, component matching, testing verification, and failure response technology research, a variety of air-cooled and water-cooled stack models have been developed. After more than 10 years of research and development, the stack power has increased from 1KW to over 100KW; the power density has improved from 1kw/L to above 5kw/L, and complete independent intellectual property rights are established. Currently, this achievement has been applied by enterprises such as Guangdong Guohong Hydrogen Energy, Zhejiang Fengyuan Hydrogen Energy, and Guangdong Himalayas Hydrogen Energy.

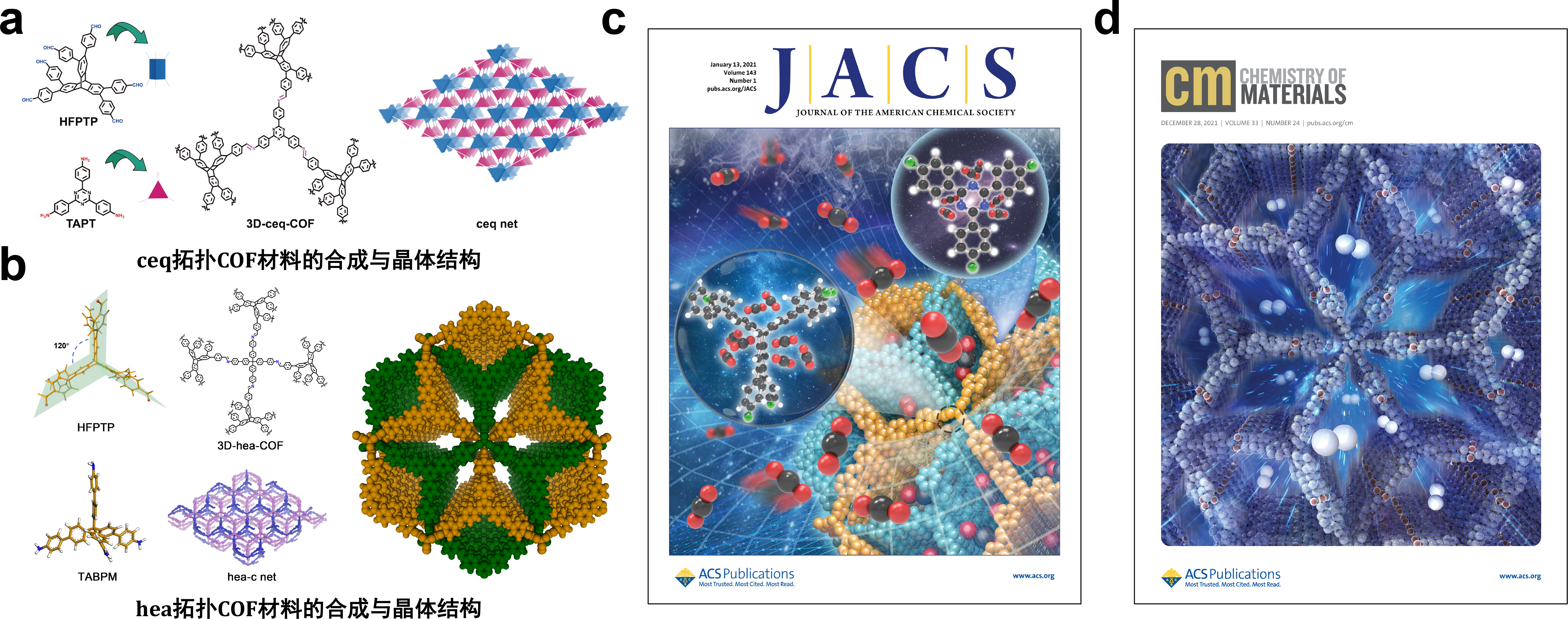

(2)Crystalline Porous Material Technology

Covalent Organic Frameworks (COFs) are a class of crystalline polymers with highly ordered pore structures and high specific surface area, which are connected by covalent bonds. They have broad application prospects in gas adsorption and storage, photoelectric conversion, heterogeneous catalysis, energy storage and conversion. However, due to the lack of effective functionalization methods and the stability issues of COFs themselves, reports on the functionalization development of such materials are very limited. Based on the theory of crystal packing energy, COFs with both high structural stability and high specific surface area have been successfully developed, solving the stability problem of COF materials. On this basis, hydrogen storage materials, CO2 capture materials, and lithium-ion transport materials based on COFs have been developed.

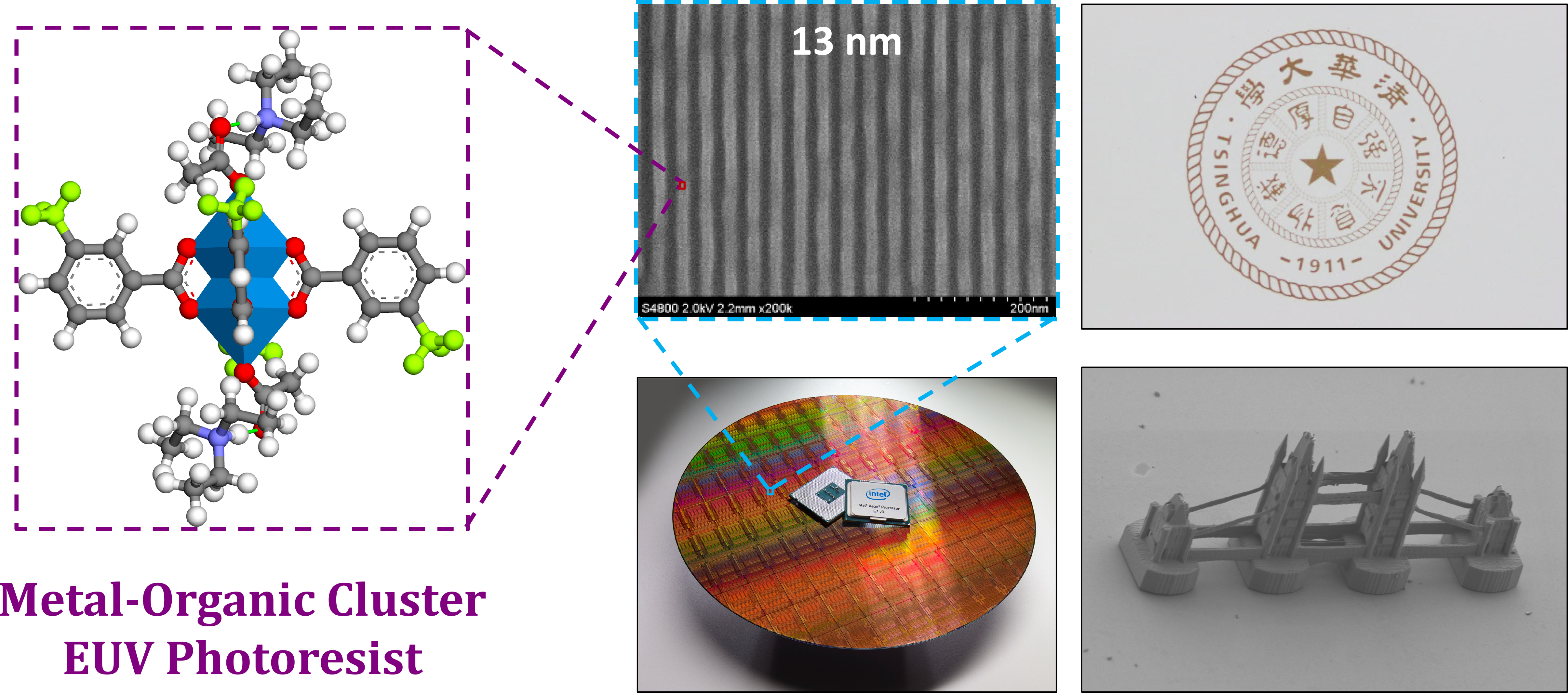

(3)Advanced Lithography Photoresist Technology

In current key semiconductor technologies, Extreme Ultraviolet (EUV) lithography is a projection lithography technique that uses an extremely short wavelength of 13.5 nm for its working light source. This technology is challenging and faces multiple bottlenecks. Due to the fact that the most advanced international EUV light sources can only provide a stable light power of 250 W, the existing polymer EUV lithography resins, which require high exposure doses, face issues such as low production capacity, high costs, and monopolies on equipment technology. High-sensitivity EUV lithography resins can effectively overcome all these bottlenecks. The laboratory has developed a series of high-sensitivity, high-resolution lithography resin materials, and related research has been published in journals such as Nature Nanotechnology, J. Am. Chem. Soc., and Mater. Today. The development of high-performance EUV lithography materials can effectively reduce the requirements for light sources and mirrors in the攻关 of EUV lithography technology challenges, and accelerate the development of domestic EUV lithography machines.

(4)Lithium-Ion Battery Safety Technology and Industrialization

The safety of lithium-ion power batteries is the most concerned issue. The Nuclear Energy Research Institute at Tsinghua University has made significant progress in addressing the safety of lithium-ion power batteries. Through the use of key material technologies with high thermal stability and battery design and preparation techniques, the internal exothermic chemical reactions in the battery are suppressed, the thermal runaway of the battery is controlled, and high-safety lithium-ion power batteries are produced. The high-performance smartphone batteries prepared do not catch fire during overcharging. The 50Ah power battery has an energy density of 200 Wh/kg, and it does not catch fire or explode when overcharged to 20V@0.5C or when heated in a full state at 150℃ for 6 hours.

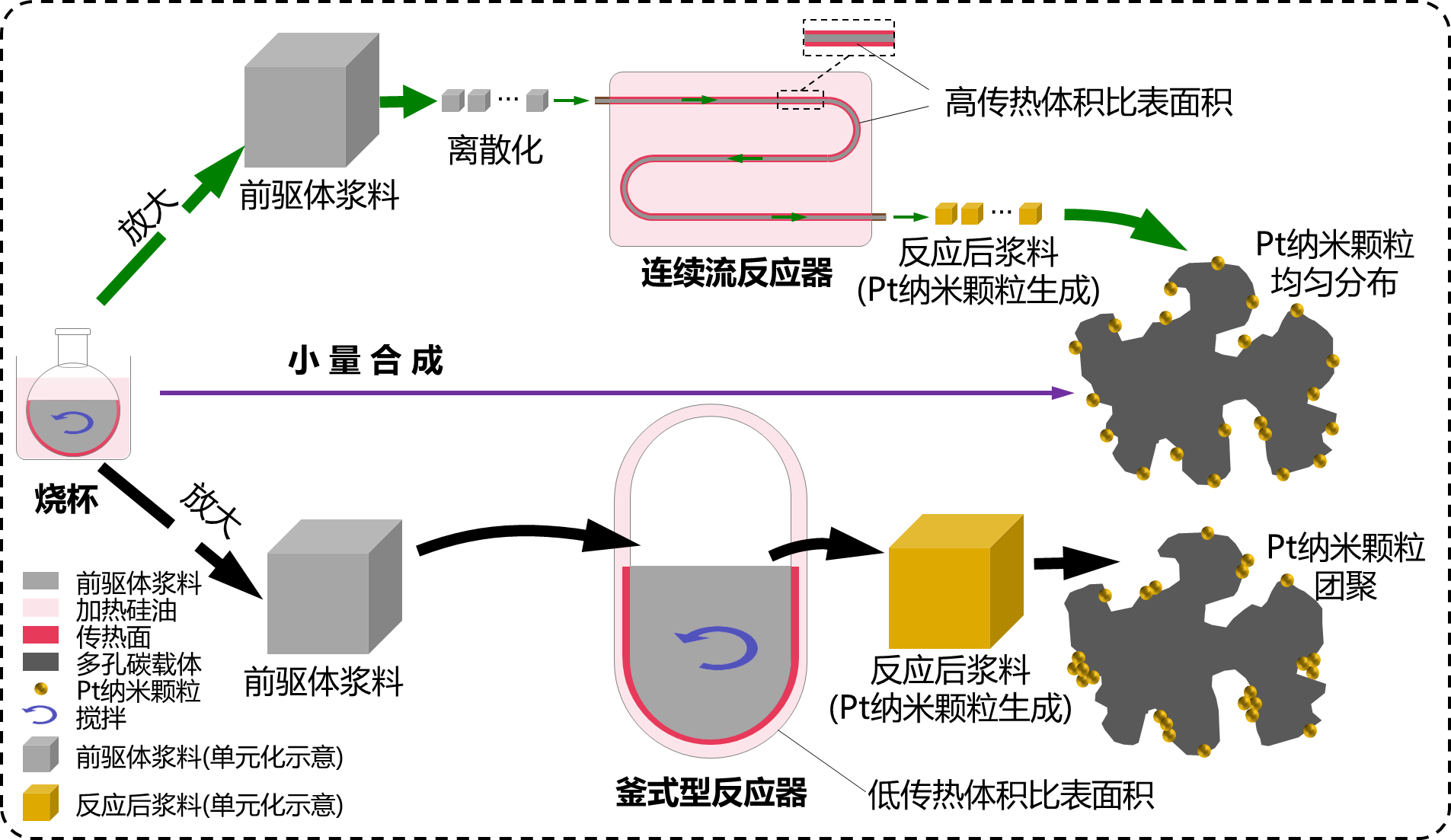

(5)Continuous Production Technology and Industrialization of Fuel Cell Catalysts

|

|

A breakthrough has been made in the traditional batch and unstable synthesis mechanism of fuel cell catalysts. A continuous flow synthesis method has been invented, and combined research, industry, education, and application have been carried out to overcome scientific and technical challenges. This has led to the development, design, and integration of a Pt/C and PtCo/C catalyst production line and core reactors, achieving mass production and large-scale application of high-performance platinum-based fuel cell catalysts. The product batch consistency is controlled within ±2%, freeing the country from the dependence on foreign suppliers for advanced electrocatalysts. The expert group of the Ministry of Science and Technology evaluated that it "fills the gap in continuous production of high-end electrocatalysts in China." This equipment has been demonstrated in the national "Hydrogen into Ten Thousand Homes" technology demonstration project, passed the new product certification in Beijing, and obtained the first batch recognition for the first machine (set) of significant technical equipment in the energy field from the National Energy Administration (recommended by Beijing).

5、Contact Us

| Prof. Cheng Wang | wangcheng@tsinghua.edu.cn |

| Prof. Xiangming He | hexm@tsinghua.edu.cn |

(Last updated, 2024-05) |